Beyond Excel: A guide to automating omnichannel stock and assortment management in 2025

The current complexity of multichannel commerce

Modern commerce has evolved drastically in recent years. Consumers expect to be able to shop anytime, anywhere. They want to find products available in both physical stores and on digital platforms. This reality has created a complex ecosystem where companies must manage multiple sales channels simultaneously.

According to the 2024 State of Commerce Report for Spain, created by Shopify, 40% of Spanish consumers show no clear preference between shopping online or in a physical store, as they enjoy both options equally. Another 40% prefer to do their shopping in physical establishments. This demonstrates how important it is for brands to offer an integrated experience that connects digital and in-person channels well.

Thinking about your shopping habits, which of the following statements applies to you?

Furthermore, 79% of Spanish shoppers tell us that it is important for brands to offer a good, integrated experience between online and offline. However, only 13% of Spanish companies state that improving their digital infrastructure to sell across multiple channels is their number one priority, in stark contrast to what consumers are demanding.

With this omnipresent and omnichannel shopper in mind, traditional inventory management, based on Excel spreadsheets and manual processes, is no longer sufficient. Companies still using these methods face constant problems. Errors multiply when trying to coordinate information between different channels. The result is a frustrating experience for both internal teams and customers.

Automating stock management has become an urgent necessity. This change requires a strategic and planned approach. It is not simply a case of buying new software. It is necessary to rethink existing processes and create new ways of working. The transition may seem overwhelming, but the benefits far outweigh the initial challenges.

Main challenges of managing stock without automation

1. Human error and outdated information

Human errors are unavoidable in manual processes and occur frequently. A simple typo can create significant discrepancies in the inventory. These errors spread across different systems and channels.

Outdated information is another critical problem. Data in Excel can become obsolete in a matter of minutes. While one salesperson is updating a spreadsheet, another may be working with completely different information. This lack of synchronisation leads to confusion and poor decisions.

2. Lack of real-time visibility

Manual inventory management does not provide immediate visibility. Managers cannot know for certain how much stock they have available at any given moment. By the time the information is collected and analysed, market conditions have already changed, and the reports are out of date before they are even completed. Sales opportunities are lost due to a lack of accurate, up-to-date data.

Coordination between different locations becomes extremely complex. Warehouses, physical stores and online platforms operate with fragmented information. And this disconnection leads to inefficiencies and missed opportunities for optimisation.

3. Stockouts and overstocking

Stockouts are one of the most costly problems in e-commerce. When a popular product sells out, sales stop immediately. Customers look for alternatives from competitors, leading to a loss of revenue and damage to the brand’s reputation.

Overstocking also represents a significant problem. Having too much inventory ties up capital and increases storage costs. Products can become obsolete before they are sold, leading to direct losses.

The lack of accurate forecasting exacerbates these problems. Without automated tools, it is difficult to anticipate future demand. Orders are based on intuition rather than on hard data. This approach leads to constant imbalances in the inventory.

4. Operational inefficiencies and high costs

Manual processes require more staff and time. Employees spend hours on administrative tasks that add no direct value. Labour costs increase without generating proportional improvements in productivity.

On the other hand, storage costs also increase. Without automated optimisation, spaces are not used efficiently. Products are stored in unsuitable locations, increasing order preparation times.

5. Inconsistent customer experience

Customers expect a personalised and seamless experience across all channels. When systems are not integrated, they may find contradictory information. A product might appear as available online but be out of stock in the physical store. Furthermore, customers expect relevant recommendations based on their purchase history. Manual systems cannot provide this level of sophistication.

Delivery promises become unpredictable. Without real visibility of the inventory, it is difficult to commit to specific dates. Delays and cancellations damage customer trust.

3 benefits of automating stock management

1. Operational efficiency

Automation eliminates repetitive, error-prone tasks. In addition, integration between different systems eliminates the duplication of work. Data is synchronised automatically between platforms. This frees up valuable time for employees to focus on strategic activities.

Automated processes run 24 hours a day. They do not need breaks or holidays. Productivity remains constant regardless of working hours. This continuity significantly improves overall efficiency.

2. Improved customer experience

With automation, customers enjoy a much more consistent experience across all channels. Stock information is updated in real time on every platform, which significantly reduces discrepancies between the online environment and physical stores.

In addition, deliveries become more predictable thanks to systems capable of calculating delivery times with greater accuracy, allowing customers to be offered reliable information about when they will receive their order. Added to this is a notable improvement in personalisation: by analysing purchasing patterns and individual preferences, the systems can generate much more relevant and effective recommendations.

3. Business scalability

Automation allows you to handle growing volumes without proportionally increasing resources. The systems can process more transactions without requiring more staff. This scalability is fundamental for sustainable growth.

Expansion into new channels is made considerably easier, and adaptation to market changes becomes more agile. Automated systems can be integrated with new platforms more easily. Companies can explore new market opportunities without operational limitations.

Essential technologies for automation

Inventory management systems are the cornerstone of any automation strategy, as they centralise stock information on a single platform and offer real-time visibility. This allows for data-driven decision-making and improved operational efficiency. In turn, technologies such as artificial intelligence and advanced analytics are transforming how inventory is managed: using predictive algorithms, they analyse demand patterns and automatically adjust stock levels, minimising stockouts and optimising availability.

Thanks to analytics, it is possible to identify consumer trends and anticipate needs, which contributes to a more seamless customer experience. Furthermore, integration via APIs allows existing systems to be connected without needing to be replaced, facilitating the exchange of information between platforms.

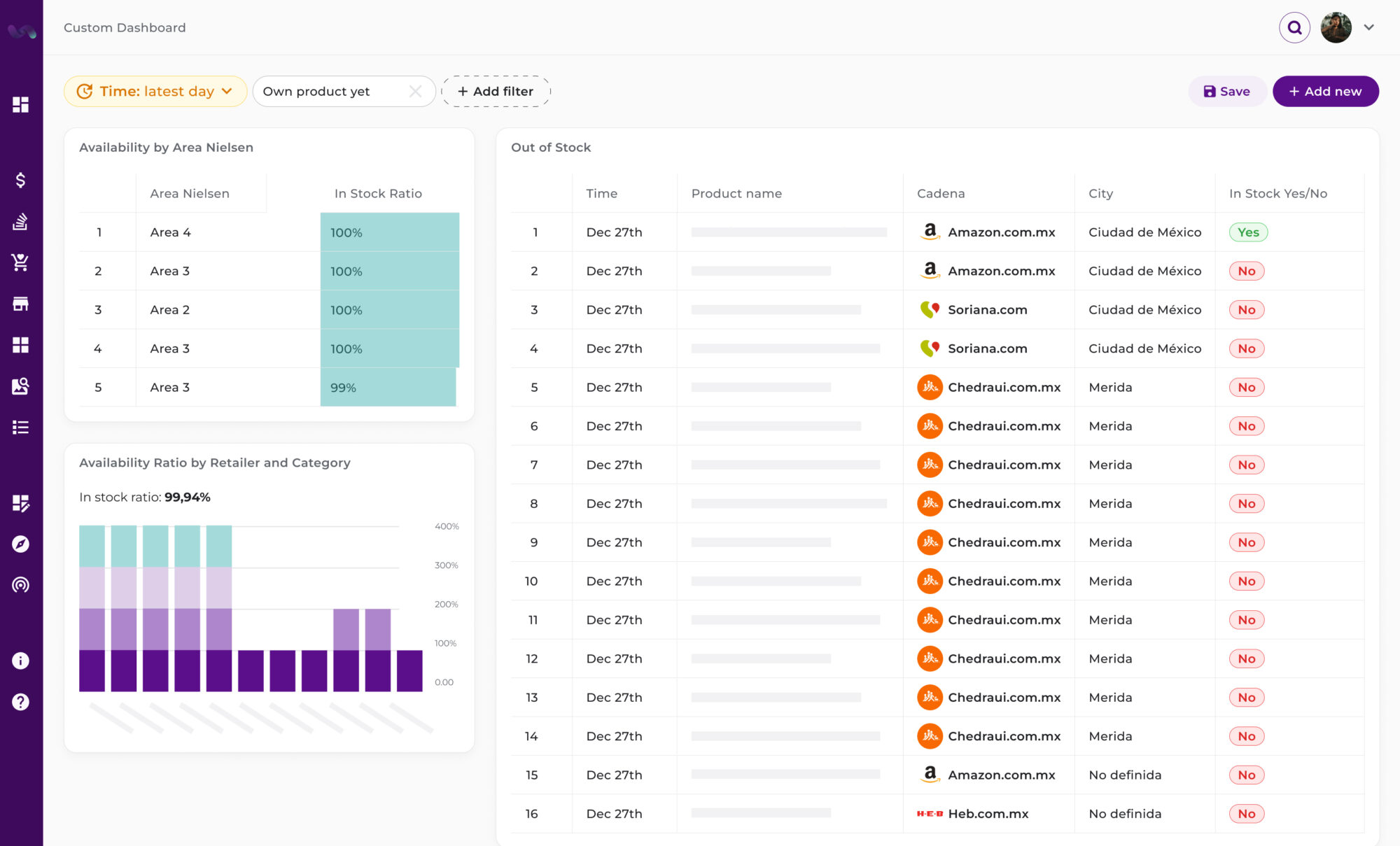

In today’s market, there are technological solutions for stock and assortment control, such as flipflow, that allow inventory management to be automated effectively.

These tools combine real-time control and advanced analytics to reduce costs, improve efficiency and guarantee assortment availability. Adopting these technologies is key to getting the most out of automation and staying competitive in the face of modern consumer expectations.

A step-by-step guide to implementing automation

Step 1: Audit your current situation

Start by documenting all existing inventory management processes. Identify every step your team follows from receipt to sale. Next, map the information flows between different departments and systems. This will allow you to visualise how information circulates within the organisation. Evaluate the technological tools you already use. Determine which ones are working correctly, which require improvements, and what integrations exist or are needed for smoother communication between systems.

At the same time, analyse historical inventory data. Examine turnover patterns, seasonality and demand trends. This information will be valuable for configuring the automated systems.

Finally, identify the most critical pain points in the current processes, prioritising those that have the greatest impact on the business, as they will be the first ideal candidates for automation.

Step 2: Select the right technological tools

Research the different options available on the market, carefully comparing their features, prices and integration capabilities. Consider both specialised solutions and comprehensive platforms, depending on your business needs. Evaluate their compatibility with your existing systems and ensure they can be integrated without major disruption.

Consider future scalability. Choose solutions that can grow with your business. Avoid tools that will require frequent replacement due to capacity limitations.

Before making a final decision, request demonstrations and pilot tests to experience the tools first-hand. Also involve end-users in the evaluation, as their experience will be key to a successful implementation.

Step 3: Implement automated processes

Start with simple, low-risk processes. Automate repetitive tasks that do not require complex decisions. This allows the team to adapt gradually to the changes.

On the other hand, configure integrations between existing systems. Establish automatic data flows between platforms. Ensure that the information is synchronised correctly. Schedule alerts for exceptional situations so that the systems can notify you when anomalies or errors are detected.

Do not forget to document all the new processes, creating guides for the team. This documentation will make future problem-solving and training easier.

Step 4: Test and adjust

Before the launch, carry out exhaustive tests in a controlled environment, simulating different scenarios to detect and correct potential faults. Involve end-users in this process, as their feedback on usability can reveal problems that are not obvious to the technical team.

Adjust the configurations based on the results, optimising performance and customising alerts according to actual needs. In addition, develop contingency plans that include backup procedures to minimise the impact of any unexpected interruption.

Step 5: Monitor, measure and continuously optimise

Define specific indicators to measure the performance and success of the automation. Include metrics for accuracy, efficiency and customer satisfaction.

Implement dashboards and automatic reports, to be able to visualise important data clearly and accessibly. In addition, the reports should provide actionable insights.

Markets and needs are constantly changing. That is why the systems will need to evolve to maintain their effectiveness. Review and adjust them regularly.

Step 6: Train your team

Develop practical training programmes tailored to each role, ensuring all users understand how the new systems work. Supplement the training with accessible reference materials, such as quick guides and tutorials, so that employees can resolve common queries themselves.

Also establish an internal support system with trained staff who can provide agile and effective help. Finally, foster a culture of continuous improvement, encouraging the team to propose optimisations, as end-users often contribute valuable ideas for perfecting processes.

Conclusion, key considerations and mistakes to avoid

Automating stock management is an essential transformation for companies operating across multiple channels. More than a technological improvement, it represents a necessary evolution to remain competitive in the current environment.

Success depends on a strategic, planned approach. Companies that adopt automation as an integrated project achieve better results than those that apply isolated solutions. A key factor is data integration: systems must communicate with each other to offer a unified view of the business, as fragmented information significantly limits its benefits.

Team training is also critical. Even the best systems will fail if users do not adopt them properly. That is why investing in training and support is as important as the technology itself.

Automating everything at once is usually a mistake. A gradual implementation allows problems to be detected and corrected without affecting critical operations, reducing risks and facilitating adaptation. In addition, it is vital to manage resistance to change: clear communication about the benefits and job security helps to build acceptance.

Automation does not have an end point. It is a constant process of improvement and adjustment. Although the path involves challenges, the benefits far outweigh the initial costs: greater efficiency, accuracy and customer satisfaction. In short, the future of commerce belongs to those who adopt automation with intelligence and strategic vision. Those who continue to rely on manual processes will be left at a disadvantage in increasingly demanding markets.